DBP SIDING

CIRCULAR BIOBASED COMPOSITE

FACADE CLADDING

HOME » MARKETS » CONSTRUCTION » DBP SIDING

WHY

DBP SIDING

CIRCULAR BIOBASED COMPOSITE FACADE CLADDING

DBP SIDING is manufactured from 100% residual waste. The upcycled biobased composite Compodeen WFC consists of 70% wood fibre and 30% polypropylene (rPP).

The wood fibre comes from unpainted scrap wood, end-of-life pallets and PEFC certified residual streams, among others. The post consumers waste Share of PP is selected from PMD residual waste. Thanks to the wood fibre, untreated Compodeen has natural ageing – with no risk of degradation.

Because Compodeen is reusable multiple times and stores CO₂ for at least 100 years, it is permanent CO₂ storage. Moreover, DBP SIDING is delivered to size to avoid construction waste.

UPCYCLING:

DBP SIDING

MADE OF

100% RESIDUAL WASTE

DBP siding is made from COMPODEEN – a bio-based composite, fully upcycled from secondary raw materials. 70% wood fibre derived from A wood and PEFC certified residual streams bonded with 30% rPP from household PMD residual waste. The ultimate form of upcycling: two low-grade waste streams transformed into an end product with sustainability class 1 (NEN-EN 350).

The amount of CO2 stored is: -13,153 kg/m2

- BIOBASED

- RECYCLABLE / CIRCULAR

- NO TREE FELLING

- FROM SECONDARY RAW MATERIALS

- PERMANENT CO2 STORAGE

- NO ENVIRONMENTALLY HARMFUL ADDITIVES

- DUTCH MANUFACTURER

- NATURAL GREYING

POSSIBLE COLOURS

STANDARD NATURAL SHADES

◼︎ BRUSHED

◼︎ WOOD PRINT

OTHER COLOUR OPTIONS

IN YOUR OWN PROJECT COLOUR

◼︎ TRANSPARENT STAINS

On a project basis, we can also offer deviating colors in addition to our standard colors.

This can be a transparent colour stain or an opaque RAL colour.

Ask about the possibilities.

◼︎ OPAQUE RAL COLOURS

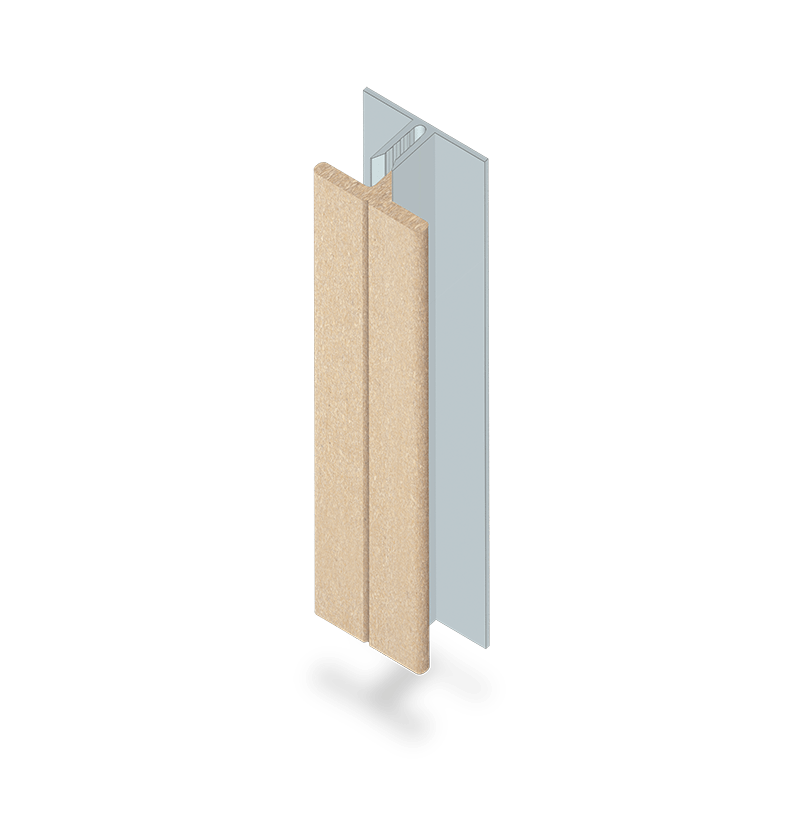

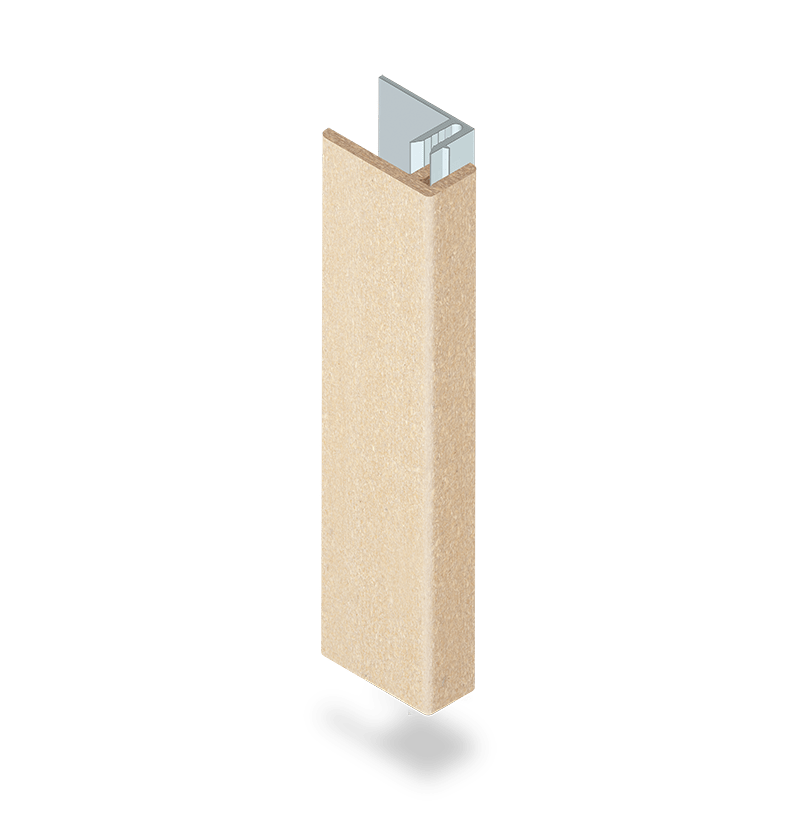

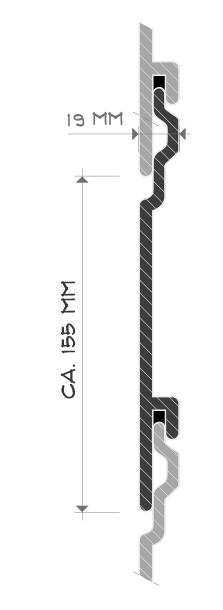

TYPE: CHANNEL

MODEL:

CHANNEL

◼︎ Profile hight: appr. 195 mm.

◼︎ Effective height: appr. 155 mm.

◼︎ Standard length: 3600* mm.

* On a project basis, we prefer to deliver the profiles by length. This prevents waste on the construction site. We shred leftover pieces and reuse them in full as raw materials for new facade cladding.

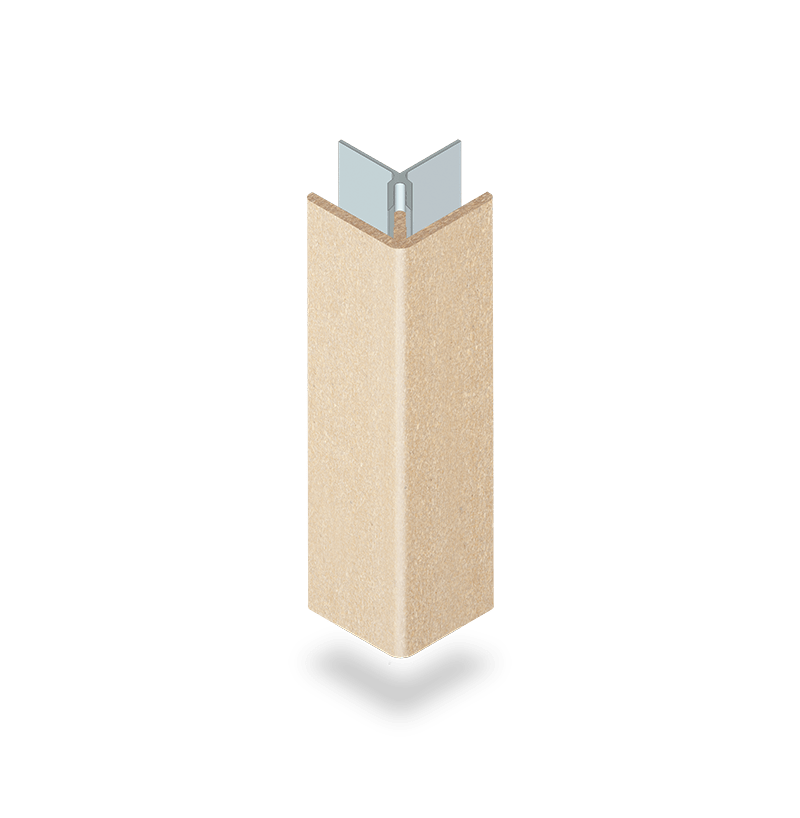

ALL ADDITIONALPROFILES

DILATIONS

Dilatations can be carried out in two ways.

– Open dilatation: this involves maintaining a dilatation in half-brick bond.

– Expansion profile: here, the seam between the façade sections is covered with a profile.

Always perform dilatations according to the applicable processing instructions.

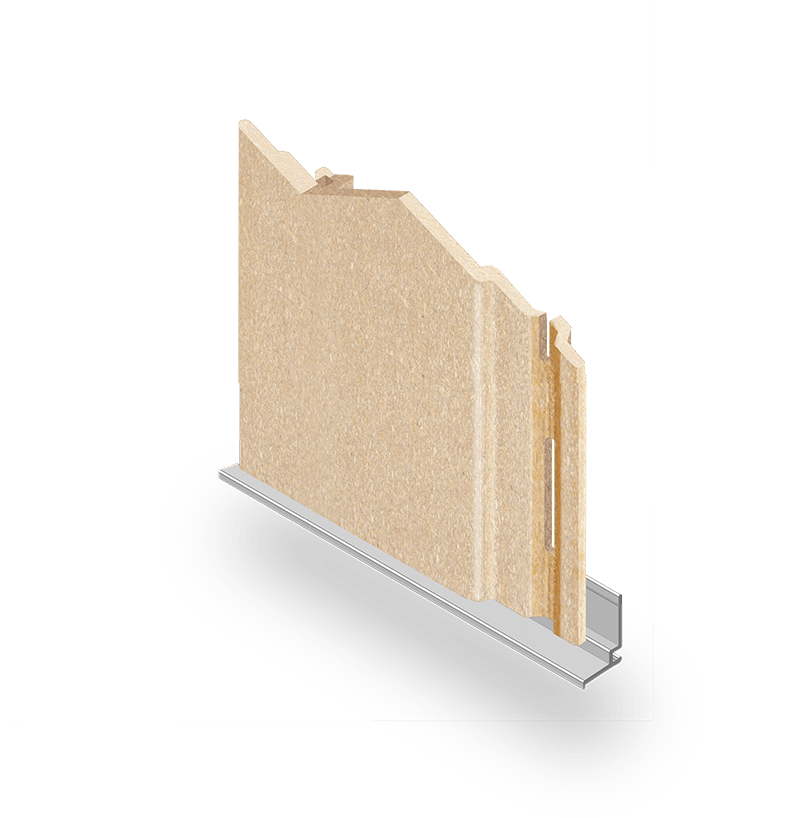

ALL CONNECTIONDETAILS

HORIZONTAL

All details are based on SBR reference details and are for illustrative purposes only.