DBP HOUSING

CIRCULAR BIOCOMPOSITE

BUILDING SYSTEM

HOME » MARKETS » CONSTRUCTION » DBP HOUSING

WHY

DBP HOUSING

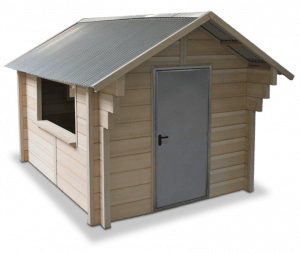

The DBP HOUSING system is notable for its simplicity in construction and versatility in terms of possibilities and applications. This makes the system extremely suitable for emergency housing in problem areas such as shelter for refugees, emergency hospitals and other primary facilities. This system is also used as an extension to existing homes or as a garden house or outbuilding. Thanks to its modular structure, DBP HOUSING offers you complete design freedom. DBP HOUSING is manufactured from 100% residual waste. The upcycled biobased composite Compodeen WFC consists of 70% wood fibre and 30% polypropylene (PP). The wood fibre comes from unpainted scrap wood, end-of-life pallets or PEFC-certified residual streams, among others. The PP share comes from the PMD residual waste you and I present to the waste processor. Thanks to its biofibre, Compodeen has natural greying just like wood – with no risk of degradation. As compodeen does not degrade and is fully reusable, it has a permanent CO2 storage.

Revolutionary!

UPCYCLING:

DBP HOUSING

HERGESTELLT AUS

100% RESTMÜHL

The share of wood fibre comes for example from, broken or old pallets, packaging material and unpainted scrap wood, also known as A-wood. The remaining component is PP, one of the most environmentally friendly plastics available. This ‘post consumers waste’ plastic literally comes from the well-known PMD waste bin or bag.

- BIOBASED

- RECYCLABLE / CIRCULAR

- PERMANENT CO2 STORAGE

- UPCYCLED FROM 100% RESIDUAL WASTE

- PEFC CERTIFIED

- SHAPE AND WEAR RESISTANT

- EASY TO APPLY

- DESIGN FREEDOM

- NATURAL GREYING

- WEATHERPROOF, WITHOUT TREATMENT

- INSENSITIVE TO TERMITES

DAS

DBP HOUSING SYSTEEM

The construction method is based on the Swedish log cabin method of interlocking wall profiles for a very strong construction.

The system is characterized by the practically infinite flexibility in design, shape, layout and dimensions. The system is characterized by the practically infinite flexibility in design, shape, layout and dimensions. There is a wide choice of doors, windows, roof plates, floors, finishes and accessories. The hollow wall profiles provide good insulation and the chambers in the profiles also ensure that cable and pipework can be neatly concealed.

DESIGN UND FREIHEIT

During the design phase, clients have complete freedom to indicate and discuss requirements and wishes. We also look together at the application and the location so that we can test this against the local building requirements and regulations.

NO BUILDING KNOWLEDGE REQUIRED

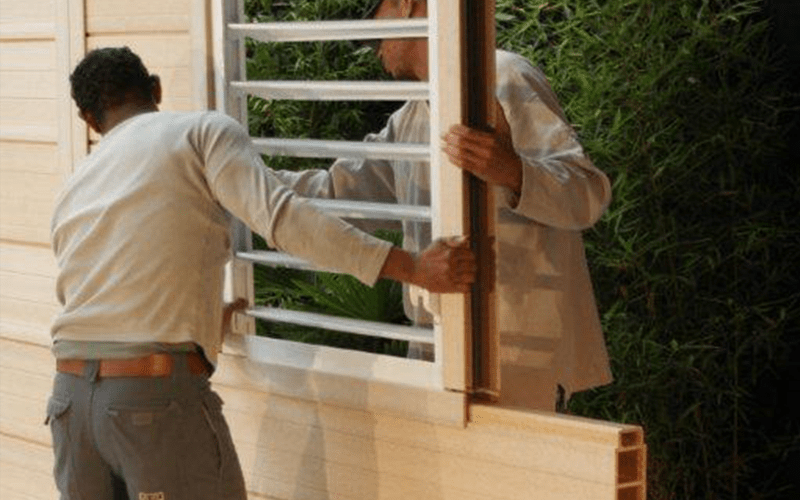

The system is accompanied by instructions with clear drawings in which the construction is guided step by step from start to finish.

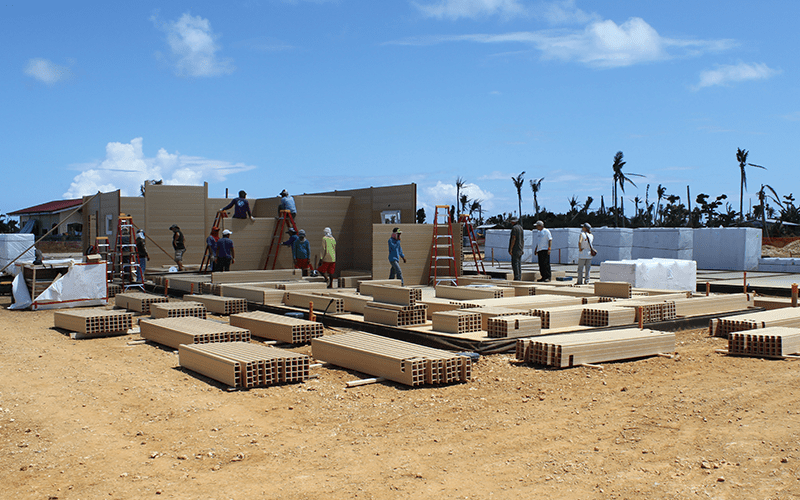

The units are very easy to assemble. No specific construction knowledge or specialist tools are required for this. All building components are clearly marked and delivered prefabricated, so nothing needs to be custom made on site. The wall profiles are stacked and interlock lengthwise and at the corners. There is no need to screw or glue. The trusses, roof panels and cover profiles are secured by means of nuts, bolts and screws. The simple, modular assembly makes the building equally easy to dismantle, adapt, expand or relocate.

SPECIAL

FINISHING

For sterile applications such as treatment and operating rooms or for technical rooms, it is possible to choose a special PVC wall, ceiling and floor finish.

CONSTRUCTIVE PERFORMANCE

The units are designed to fully meet customer requirements with due regard for local regulations. When the design is final, a technical data sheet is compiled, complete with all necessary construction calculations. These documents must be submitted for inspection and control to the local building inspection.

COMPLIES

WITH LOCAL

REGULATIONS