GENERIC

PROPERTIES

COMPODEEN

COMPODEEN WFC

BIOBASED WOOD FIBRE COMPOSITE

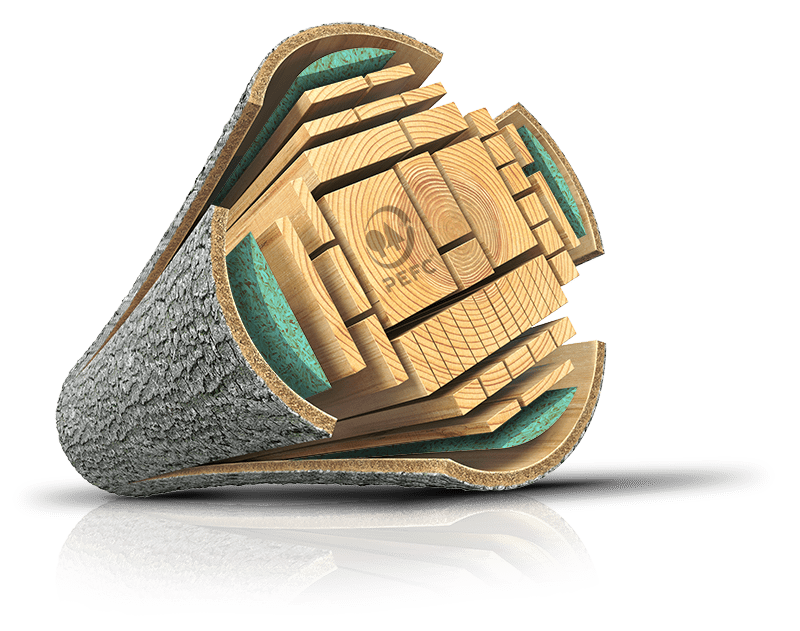

COMPODEEN WFC is a circular and weather-resistant biobased composite. The main component consists of wood fibre, supplemented with polypropylene. PP is one of the most environmentally friendly plastics available because it is excellent for recycling.

The two materials are combined and extruded under high pressure. As a result, weather influences have no negative impact on the service life. The wood fibres are positioned in the lengthwise in this patented process, resulting in exceptional strength. During the production of Compodeen, residual material is very easily reused for new material without loss of quality. Of course, this also applies to – applied in practice – Compodeen.

- Biobased

- 100% circular / recyclable

- Permanent CO2 storage

- Low maintenance

- Resistant to termites

- Anti slip

- Low expansion coefficient

- High rigidity

- Does not splinter

- No treatment needed

- Natural greying

- No treatment needed

- Does not leach

- Contains no preservatives

- Can be painted over

- Easy to process

- Wear resistant

- Long lifespan

COMPODEEN does not degrade and is fully circular,

that is why there is permanent CO2 storage.

The PEFC-certified wood fibre comes from residual streams from sustainably managed forests.

Green indicated in the image.

UPCYCLING:

BASIC MATERIAL

FROM 100% RESIDUAL WASTE

![]() 30% – post consumer waste PP – derived from PMD residual waste

30% – post consumer waste PP – derived from PMD residual waste![]() 70% – wood fibre – from old broken pallets and unpainted scrap wood

70% – wood fibre – from old broken pallets and unpainted scrap wood